Sublimation printing has become the gold standard for custom jerseys, Dri-Fit tees, and event wear. It offers vibrant, long-lasting prints that don’t crack, peel, or fade. Whether you're from a school, sports team, or corporate organisation, understanding how sublimation works can help you choose better apparel that looks great and lasts longer.

This guide takes you through the sublimation process from start to finish, with clear visuals for each step.

Every great print starts with a great design.

Every great print starts with a great design. Before anything gets printed, the artwork is created digitally using graphic software. At this stage, logos, colours, and placement are finalised to ensure a sharp, professional result.

Once the design is ready, it’s printed in reverse onto sublimation transfer paper using special sublimation inks. These inks are designed to convert from solid to gas under heat, which is key to the sublimation process.

Heat Transfer onto Fabric

The printed transfer paper is then placed on the polyester garment, and a heat press is used to apply high heat and pressure. This process transfers the design onto the fabric.

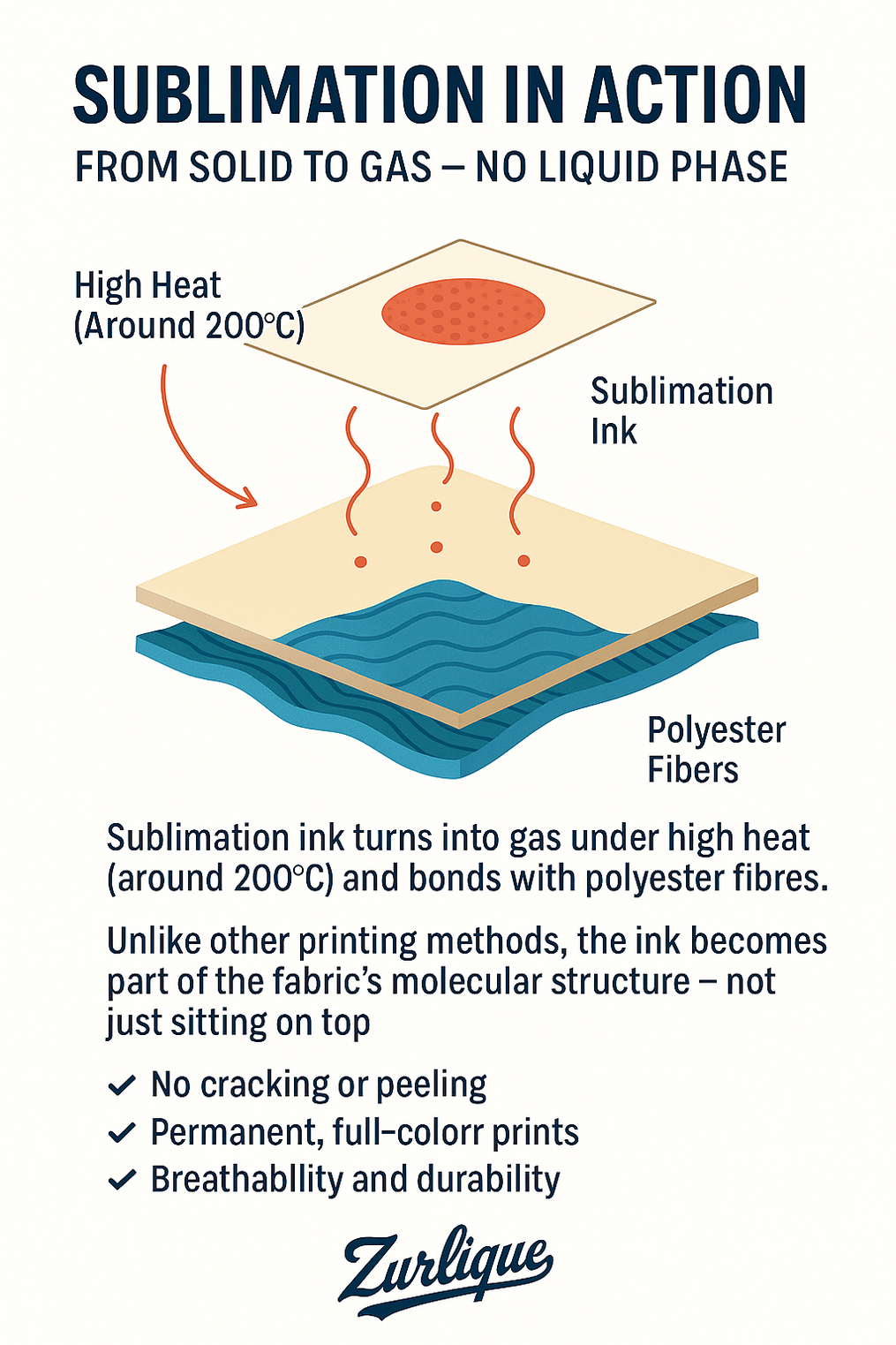

Sublimation in Action (Technical View)

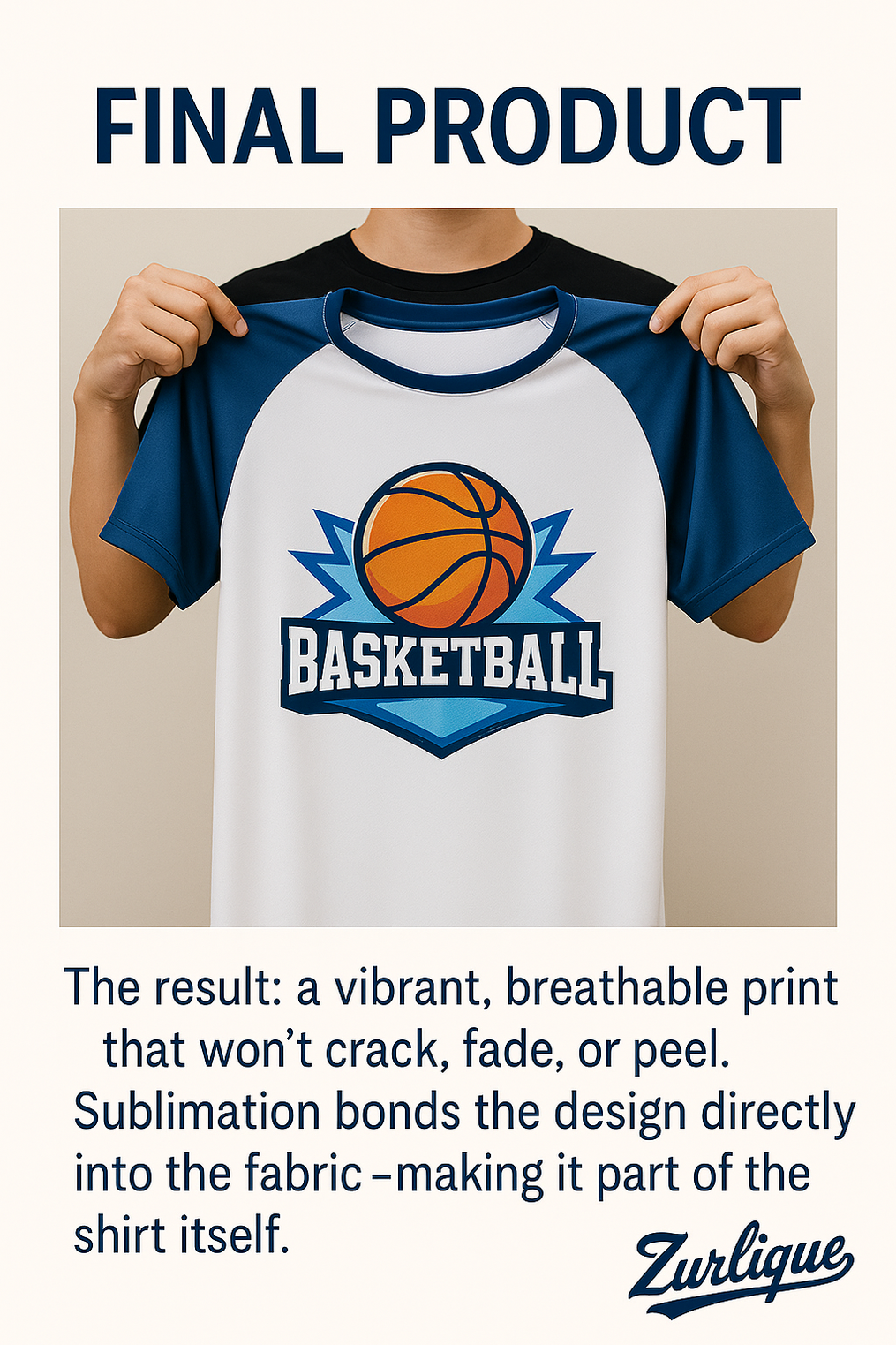

Final Result: Durable, Vibrant Sublimation Prints

The end product? A lightweight, breathable garment with a full-colour print that won’t fade or peel. Perfect for school uniforms, team jerseys, or corporate event wear.

Ready to Customise Your Own?

Zurlique offers sublimation printing for schools, teams, and events in Singapore. Get high-quality, one-of-a-kind teamwear that lasts.

📞 WhatsApp 9774 8888

🌐 Visit www.zurlique.com

Write a comment